SV-F 1

Sizes:

19×8.5 | 19×9 | 19×9.5 | 19×11

20×8.5 | 20×9 | 20×10 | 20×11 | 20×12

22×9 | 22×9.5 | 22×10 | 22×11

Sizes:

19×8.5 | 19×9 | 19×9.5 | 19×11

20×8.5 | 20×9 | 20×10 | 20×11 | 20×12

22×9 | 22×9.5 | 22×10 | 22×11

Stronger, lighter wheels for optimal performance and looks!

Performance Proven

Another level of customization

Precision Engineered

![]()

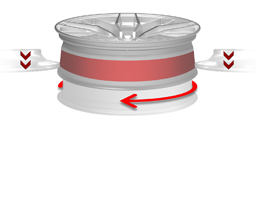

The process starts using a casting specially made for Flow Forming Technology that’s placed onto a steel rim that’s then prepped for molding.

Extensive heat and pressure is applied using three individual rollers to shape the aluminum to the wheel mold.

The individually shaped rollers fortify the barrel to the specified width and density, allowing for a stronger wheel using less material.

The molecular compound of the aluminum significantly hardens in a streamline direction, resulting in a tolerant and considerably lighter wheel.

Sizes:

20×8.5 | 20×9 | 20×10 | 20×11 | 20×12

22×9 | 22×11 | 22×12

Stronger, lighter wheels for optimal performance and looks!

Performance Proven

Another level of customization

Precision Engineered

![]()

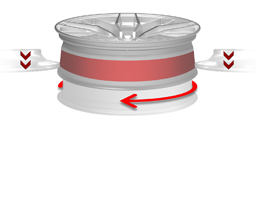

The process starts using a casting specially made for Flow Forming Technology that’s placed onto a steel rim that’s then prepped for molding.

Extensive heat and pressure is applied using three individual rollers to shape the aluminum to the wheel mold.

The individually shaped rollers fortify the barrel to the specified width and density, allowing for a stronger wheel using less material.

The molecular compound of the aluminum significantly hardens in a streamline direction, resulting in a tolerant and considerably lighter wheel.

Sizes:

20×8.5 | 20×9 | 20×9.5 | 20×10 | 20×11

21×9 | 21×9.5 | 21×10.5 | 21×12

22×9 | 22×11 | 22×12

Stronger, lighter wheels for optimal performance and looks!

Performance Proven

Another level of customization

Precision Engineered

![]()

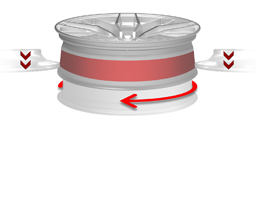

The process starts using a casting specially made for Flow Forming Technology that’s placed onto a steel rim that’s then prepped for molding.

Extensive heat and pressure is applied using three individual rollers to shape the aluminum to the wheel mold.

The individually shaped rollers fortify the barrel to the specified width and density, allowing for a stronger wheel using less material.

The molecular compound of the aluminum significantly hardens in a streamline direction, resulting in a tolerant and considerably lighter wheel.